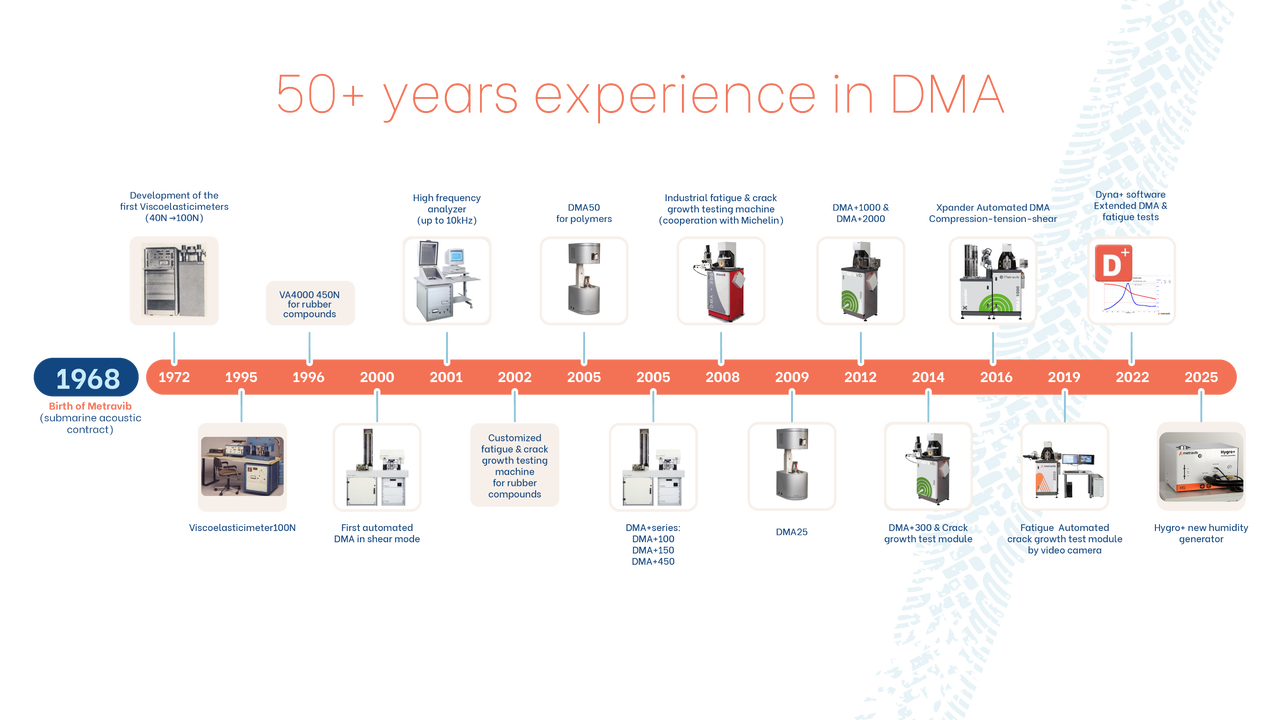

Our history

The origin of Metravib DMA comes from… acoustic engineering and the French Navy!

One of the very first DMA worldwide has been developed in 1969 by Metravib to address the Engineering group needs of characterizing viscoelastic properties of the polymer materials used to reduce the noise generated by military submarines.

From this original prototype Metravib became aware of the importance of viscoelastic properties for the industrial products performances and for the development of advanced materials.

Since 1969, Metravib is working in close cooperation with leaders of Polymer & Rubber Industry to develop testing instruments and methods meeting the expectations of scientists, compounders, research & development engineers.

This has led Metravib to offer a unique range of instrument featuring the most advanced scientific design in dynamic mechanical analyzers and covering extremely large analysis ranges of frequency, force, strain and temperature.

- 1969: Birth of Metravib as engineering company : The name Metravib means « Mesure et traitement des vibrations et du bruit », that is to say : Measurement and treatment of vibrations and noise.

- 1972: Metravib develops the first DMA : The original goal is to characterize the viscoelastic properties of damping materials over the largest possible frequency range : The absence of such an instrument on the market leads industrials companies to ask Metravib to supply them with an identical unit. First customers of Metravib in France are Citroen, Rhône Poulenc and University laboratories.

- 1974: The “Viscoelasticimeter” is born; it is a fully analog instrument, using splendid Nixie tubes display!The Metravib Viscoelasticimeter proposes 8 frequencies from 7.8125Hz up to 1000Hz with a 40N electrodynamic shaker.The production of the Metravib DMA units starts in a very artisanal way in the first years.

- 1980: The observation of strong limitations in generating significant deformation of materials specimens of respectable sizes, leads Metravib to extend the excitation force to 150N.The advent of computers led Metravib to develop a new, more sophisticated instrument, the “Viscoanalyzer”: The computer is a Nova 4C from Data General, the results are stored on 5.25-inch floppy disks. The name “Viscoanalyzer” specific to the Metravib brand, became the generic name of the time and is sometimes still used today.

- 1995: The IBM PC becomes the microcomputer standard; Metravib is developing a new range of Viscoanalyzers: VA2000, VA3000, VA4000; The analysis frequency domain is extended to very low frequencies; The maximum excitation force is also extended to 450N.

- 2000: Faced with growing demand from the tire industry, the idea of a fully autonomous instrument working continuously on a large quantity of shear specimens took shape: The ROB100 was developed to allow a sequence of continuous shear tests 7 days a week, 24 hours a day!

- 2001: Under the leadership of a major French rubber manufacturer, Metravib developed a solution to characterize the viscoelastic properties of elastomers at very high frequencies up to 10kHz: the VHF10000 is born! This is a totally unique instrument on the market!

- 2002: At the request of a leader in the tire industry, Metravib developed a machine for characterizing the cracking properties of elastomeric compounds. The customized machine is made on the basis of a VA2000 Viscoanalyzer.

- 2004: Merge of the Metravib company with the company 01dB . The resulting company 01dB-Metravib is the French specialist in vibro-acoustics engineering and instrumentation.

- 2005: The development of the use of DMA for the characterization of the glass transition of numerous polymers encourages Metravib to develop an entry-level instrument, technologically simplified and more compact, with a force reduced to 50 Newtons: The DMA50.

- 2008: The growing demand for crack growth tests leads Metravib to industrialize a specific dedicated machine.

- 2009: The DMA Desktop range is enriched with a smaller version of 25 Newtons: the DMA25 has the same performance as DMA50 with simply a reduced maximum force capacity.

- 2011: 01dB-Metravib leaves the Areva group and becomes Acoem.

- 2012: After an in-depth study of the material characterization needs of its customers, Metravib carries out a complete re-design of the mechanical, electronic and software structures; Metravib launches the new DMA+ range with two models DMA+1000 and DMA+2000 respectively integrating electrodynamic shaker of 1000 and 2000 Newtons.

- 2014: The new DMA+ series is enriched with the DMA+300 model and an optional module dedicated to crack propagation characterization.

- 2016: Metravib launches Xpander: a specimen server integrating a 6-axis robot dedicated to the DMA+series; Ultra-versatile Xpander allows you to automate tension, compression and shear tests.

- 2019: Metravib offers a new crack growth test module integrating a digital camera and real-time image processing allowing the machine to monitor crack growth tests completely autonomously.

- 2022: Metravib equips its DMA+ series with a new software: Dyna+. Bringing together all dynamic tests: DMA, fatigue, and crack growth testing, Dyna+ allows unlimited test combinations, the vast majority of which can be carried out with the Xpander robot.

- 2023: ACOEM’s Material Testing division becomes Metravib Material Testing, a subsidiary of ACOEM.

Would you like to…?